Product classification

Pre-twisted distribution cable

Classification:

Electrified railway series

Product accessories:

Product Introduction

use:

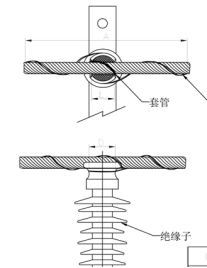

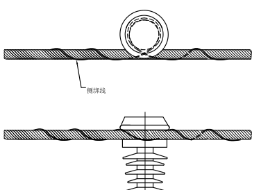

Distribution tie wires are used to fix bare wires and insulated wires in the top grooves of pin insulators and post insulators used in power distribution facilities. Compared with manual wire binding, power distribution wire binding provides a better method for fixing wires. In various forms of movement (including breeze vibration, galloping and shimmy), it provides better wear protection for the wire.

Since the rubber conduit provides an elastic buffer layer around the wire, the abrasion of the contact surface between the wire and the insulator is avoided, thereby providing better protection for the wire. When using power distribution ties on insulated wires, rubber conduits are not required.

It is suitable for the binding of pin insulators. The power distribution binding line is installed outside the return line protection strip, and the material is aluminum-clad steel.

structure:

composition:

The power distribution cable has a spiral structure and consists of two aluminum-clad steel or copper-clad steel wires. The shape of the central part can be matched with various insulators and various wires. The elastic rubber tube provides anti-wear function. The grip part is frosted to improve its gripping ability.

Features:

1. Material strength

Made of aluminum-clad steel or aluminum alloy wire, the tensile strength is much higher than the manual lashing line of soft aluminum;

2. Consistent radial pressure

Prefabricated in the factory, the inner diameter of the spiral is about 20% smaller than that of the wire. Compared with manual tying, helix provides consistent radial pressure. Loose binding wire will aggravate the wear and tear of binding wire, guard wire or wire.

3. Grip strength

On most wires, the minimum grip strength of 350 kg can be easily exceeded. To

4. Resilience

The power distribution cable provides resilience and gripping force without slipping and helps maintain sag and tension.

5. Pull off strength

The power distribution cable can resist pull-off force and upward force. The strength of the material and the ring structure provide the necessary resistance to side pull and uplift, and can prevent the wire from leaving the insulator groove.

6. Radio interference voltage

The radio interference voltage of the power distribution tying wire is equivalent to that of the well-made hand-made tying wire newly installed on intact wires and insulators. However, compared with power distribution cables that can always maintain a tight grip, hand-made knots may become loose, causing wear, and increasing radio noise levels.

7. Consistency

Each installed power distribution cable is exactly the same. To

8. Simple and convenient to use

Due to the use of factory prefabrication, the installation of the power distribution cable tie is simple and convenient. The power distribution tying line can be installed with bare hands within 30 seconds; when the live operating lever is used for live installation, the installation time does not exceed 3 minutes. The power distribution cable can be installed by hand without any tools, it is safer than the long spiral cable, and there is no danger of over-tightening.

9. Adaptability

The power distribution tying wire can be used for various wire specifications and can adapt to various types of insulator/wire combinations.

10. Prevent wear

The rubber conduit of the power distribution cable can effectively prevent wear and tear, thereby providing better protection for the wires.

Selection table of pre-twisted power distribution binding wire

|

Top binding type: suitable for pin insulator neck range 70~76mm |

|||||

|

RP Product number |

Applicable clues: bare wires and insulated wires |

Reference guard line |

Monofilament |

Color code |

weight Kg |

|

Applicable wire diameter range(mm) |

|||||

|

DTF-7606P |

10.30~11.66 |

660 |

3.26 |

blue |

0.20 |

|

DTF-7609P |

14.95~16.89 |

810 |

3.26 |

purple |

0.22 |

|

DTF-7610P |

16.90~19.19 |

830 |

3.26 |

brown |

0.24 |

|

DTF-7611P |

19.20~21.81 |

870 |

3.26 |

red |

0.26 |

|

DTF-7612P |

21.82~24.60 |

950 |

3.26 |

blue |

0.28 |

|

Note: This table only lists some products commonly used in electrified railways. If you need products with other specifications, please call Beijing Dongfang Ruineng. P stands for matching rubber conduits. Rubber conduits are not provided for power distribution binding wires for insulated conductors. |

|||||

Selection table of pre-twisted power distribution binding wire

|

Top binding type: suitable for pin insulator neck range 76~81mm |

|||||

|

RP Product number |

Applicable clues: bare wires and insulated wires |

Reference guard line |

Monofilament |

Color code |

weight Kg |

|

Applicable wire diameter range(mm) |

|||||

|

DT-8106P |

10.30~11.66 |

660 |

3.26 |

blue |

0.20 |

|

DT-8109P |

14.95~16.89 |

810 |

3.26 |

purple |

0.22 |

|

DT-8110P |

16.90~19.19 |

830 |

3.26 |

brown |

0.24 |

|

DT-8111P |

19.20~21.81 |

870 |

3.26 |

red |

0.26 |

|

DT-8112P |

21.82~24.60 |

950 |

3.26 |

blue |

0.28 |

|

Note: This table only lists some products commonly used in electrified railways. If you need products with other specifications, please call Beijing Dongfang Ruineng. P stands for matching rubber conduits. Rubber conduits are not provided for power distribution binding wires for insulated conductors. |

|||||

The pre-twisted power distribution tying line can also provide side tying to fix insulators and wires. Users who need side tying can call Beijing Dongfang Ruineng.

Previous Page

Next Page

Previous Page

Next Page

010-83711730

010-83711730